LC Anderson has been proactively helping our clients prepare their HVAC systems for the safe return of their employees, customers, students and faculty, and patients and staff. We have provided detailed information on the need to upgrade filters and assess ventilation, and more recently to consider deploying air cleaners.

This article focuses specifically on the value air purifiers bring to enhance the safety of building occupants by controlling the spread of the coronavirus, as well as other bacteria, allergens, mold, and odor.

Poor Indoor Air Quality (IAQ) has been ranked among the top 5 environmental risks to the public. According to Harvard Health, improving indoor air quality can help you feel better, heighten productivity, and even extend your lifespan. The EPA states that some pollutants are 2 to 5 times higher indoors where the average American spends 90% of their time. Common indoor air pollutants have been linked to a higher risk of illness, cancer, pneumonia, and asthma. COVID-19 has forever changed our perspective on cleanliness, personal interaction, and our environment, and it has made IAQ a chief concern.

Your HVAC system plays a role in controlling the spread of the coronavirus and other indoor contaminants. ASHRAE has publicized clear guidance on improving filtration and ventilation (air changes) as we reopen buildings.

LC Anderson has been working diligently with industry experts to present you with the most cost-effective way to make your building safer through enhancements to your HVAC system. Because normal filtration methods alone do not work against viruses and increasing outdoor air is not a sustainable solution, more direct methods of killing them off are called for. Installing proven air purification in the HVAC system is an IAQ approach to battle contaminants head-on. UV light systems are effective for killing bacteria, mold, and viruses on HVAC coils, but UV is not a viable solution for improving IAQ and killing airborne viruses in the space.

We have had very positive results with devices employing the bipolar ionization technology (BPI) to neutralize microbes (including viruses) and this may also lower outside air requirements by reducing particulate and volatile organic compounds (VOC).

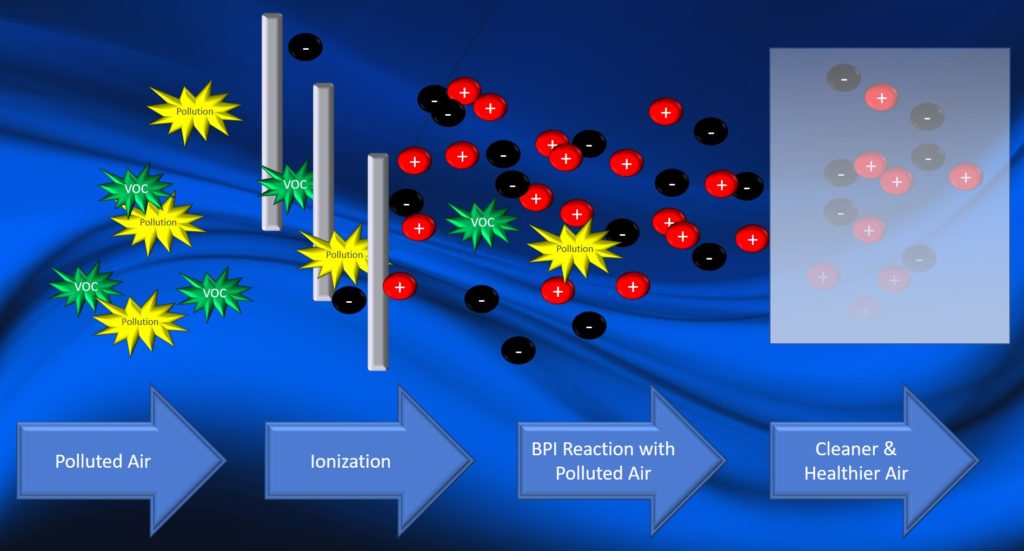

When a molecule is decomposed into atoms, free electrons are generated. Negative ions are molecules with free electrons and positive ions are molecules lacking an electron. These bipolar ions (negative and positive) are unstable and will seek out atoms and molecules in the air with which to trade electrons. When return air passes over the in-line BPI device, positive and negative ions are produced by the device and broadcast into the space to combine with viruses, allergens, particles, smoke, and odors in the air. When the ions encounter viruses, bacteria, or mold, their reaction decomposes proteins on the surface of these pathogens, thereby inhibiting their activity. The ions also attach to allergens like pollen and other particles like dust and dander, causing them to band together until they are large enough to drop to the floor or be caught by the air filter in your ventilation system.

BPI technology generates the same ions that nature creates with lightning, waterfalls, and ocean waves. Nature uses energy to break apart molecules, naturally cleaning the air and producing a healthier environment. The only difference between BPI technology and nature is that BPI technology does it without developing harmful ozone levels.

Many air cleaning technologies have been developed specifically to combat viruses, bacteria, mold, and allergens over the years. LC Anderson recommends only the most proven air purification technologies that provide extensive objective quality evidence, third-party testing to validate they kill viruses, bacteria, mold, and allergens. Each application is unique, and we match the best total solution to meet your cost, performance, and lead time requirements.

As mentioned, BPI technology decreases the “outside air dilution” required per the ASHRAE 62.1 ventilation standard. This is a real advantage. Outside air can have pollutants that do not improve the IAQ, such as mold, allergens, and diesel and automotive exhaust gasses. Bipolar ionization can reduce most contaminants without being diluted with outside air through the building’s mechanical ventilation systems. This provides an alternative IAQ procedure that not only lessens the amount of outside air needed, but also lowers the particulate count as well as the static charge in the air, kills microbials, and eliminates odors.

The application of these ions results in cleaner and healthier indoor air while saving energy that would have been required to heat, cool, and dehumidify the higher volume of outside air. It may also save the cost of extensive HVAC system renovations or upgrades, and on new projects, it may allow for downsizing mechanical systems with ongoing energy savings.

At the time of this article, ASHRAE has produced little guidance on air purifiers since they consider them to be emerging technologies with limited independent third-party testing. The industry must quickly step up efforts to qualify proven air purification technologies and improve building safety.

LCA is committed to working with engineers and air purification leaders to provide thoughtful and proven recommendations to all our customers. We intend to help acquire the necessary in-service data to assist ASHRAE in developing fact-based guidance on air purification technologies.

Until then, LC Anderson will continue to provide product recommendations, detailed proposals, installation services, and validation testing to ensure the air purification systems perform as intended.

For questions or to schedule an appointment send us a message or give us a call.